WO1998036335A2 - Process control system using a layered-hierarchy control strategy distributed into multiple control devices - Google Patents

Process control system using a layered-hierarchy control strategy distributed into multiple control devices Download PDFInfo

- Publication number

- WO1998036335A2 WO1998036335A2 PCT/US1998/001573 US9801573W WO9836335A2 WO 1998036335 A2 WO1998036335 A2 WO 1998036335A2 US 9801573 W US9801573 W US 9801573W WO 9836335 A2 WO9836335 A2 WO 9836335A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- conttol

- modules

- user

- routine

- conttoller

- Prior art date

Links

Classifications

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F8/00—Arrangements for software engineering

- G06F8/60—Software deployment

- G06F8/61—Installation

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/418—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS], computer integrated manufacturing [CIM]

- G05B19/41865—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS], computer integrated manufacturing [CIM] characterised by job scheduling, process planning, material flow

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F8/00—Arrangements for software engineering

- G06F8/10—Requirements analysis; Specification techniques

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F9/00—Arrangements for program control, e.g. control units

- G06F9/06—Arrangements for program control, e.g. control units using stored programs, i.e. using an internal store of processing equipment to receive or retain programs

- G06F9/44—Arrangements for executing specific programs

- G06F9/445—Program loading or initiating

- G06F9/44505—Configuring for program initiating, e.g. using registry, configuration files

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/31—From computer integrated manufacturing till monitoring

- G05B2219/31474—Icon display for quick access of detailed information

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32162—Tasks or control icons are linked to form a job

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/36—Nc in input of data, input key till input tape

- G05B2219/36025—Link, connect icons together to form program

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/36—Nc in input of data, input key till input tape

- G05B2219/36076—Select icon and display corresponding instructions

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/36—Nc in input of data, input key till input tape

- G05B2219/36143—Use of icon to represent a function, part of program

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/02—Total factory control, e.g. smart factories, flexible manufacturing systems [FMS] or integrated manufacturing systems [IMS]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/80—Management or planning

Definitions

- This invention relates to process control systems. More specifically, the present invention relates to a process control system which monitors and uniformly displays diagnostic information of devices of multiple different types.

- Present-day process control systems use instruments, control devices and communication systems to monitor and map ⁇ ruate control elements, such as valves and switches, to maintain at selected target values one or more process variables, mcluding temperature, pressure, flow and the like.

- the process variables are selected and controlled to achieve a desired process objective, such as attaining the safe and efficient operation of machines and equipment utilized in the process.

- Process control systems have widespread application in the automation of industrial processes such as the processes used in chemical, petroleum, and manufacturing industries, for example.

- Control of the process is often implemented using microprocessor-based controllers, computers or workstations which monitor the process by sending and receiving commands and data to hardware devices to control either a particular aspect of the process or the entire process as a whole.

- the specific process control functions that are implemented by software programs in these microprocessors, computers or workstations may be individually designed, modified or changed through programming while requiring no modifications to the hardware.

- an engineer might cause a program to be written to have the controller read a fluid level from a level sensor in a tank, compare the tank level with a predetermined desired level, and then open or close a feed valve based on whether the read level was lower or higher than the predetermined, desired level.

- the parameters are easily changed by displaying a selected view of the process and then by modifying the program using the selected view.

- the engineer typically would change parameters by displaying and modifying an engineer's view of the process.

- software programs In addition to executing control processes, software programs also monitor and display a view of the processes, providing feedback in the form of an operator's display or view regarding the status of particular processes.

- the monitoring software programs also signal an alarm when a problem occurs.

- Some programs display instructions or suggestions to an operator when a problem occurs.

- the operator who is responsible for the control process needs to view the process from his point of view.

- a display or console is typically provided as the interface between the microprocessor based controller or computer performing the process control function and the operator and also between the programmer or engineer and the microprocessor based controller or computer performing the process control function.

- Systems that perform, monitor, control, and feed back functions in process control environments are typically implemented by software written in high-level computer programming languages such as Basic, Fortran or C and executed on a computer or controller.

- a process control program might be written in Fortran and require two inputs, calculate the average of the inputs and produce an output value equal to the average of the two inputs.

- This program could be termed the AVERAGE function and may be invoked and referenced through a graphical display for the control engineers.

- a typical graphical display may consist of a rectangular block having two inputs, one output, and a label designating the block as AVERAGE.

- a different program may be used to create a graphical representation of this same function for an operator to view the average value.

- these software programs are placed into a library of predefined user selectable features. The programs are identified by function blocks.

- a user may then invoke a function and select the predefined graphical representations to create different views for the operator, engineer, etc. by selecting one of a plurality of function blocks from the library for use in defining a process control solution rather than having to develop a completely new program in Fortran, for example.

- a group of standardized functions, each designated by an associated function block, may be stored in a control library.

- a designer equipped with such a library can design process control solutions by interconnecting, on a computer display screen, various functions or elements selected with the function blocks to perform particular tasks.

- the microprocessor or computer associates each of the functions or elements defined by the function blocks with predefined templates stored in the library and relates each of the program functions or elements to each other according to the interconnections desired by the designer.

- a designer could design an entire process control program using graphical views of predefined functions without ever writing one line of code in Fortran or other high-level programming language.

- New process control functions are designed primarily by companies who sell design systems and not by the end users who may have a particular need for a function that is not a part of the standard set of functions supplied by the company.

- the standardized functions are contained within a control library furnished with the system to the end user.

- the end user must either utilize existing functions supplied with the design environment or rely on the company supplying the design environment to develop any desired particular customized function for them. If the designer is asked to modify the parameters of the engineer's view, then all other views using those parameters have to be rewritten and modified accordingly because the function program and view programs are often developed independently and are not part of an integrated development environment. Clearly, such procedure is very cumbersome, expensive, and time-consuming.

- process control systems are typically constrained to a particular size and difficult to adapt over time to arising needs.

- process control systems are inflexible in configuration, often requiring a complete software revision for the entire system when new devices are incorporated.

- the conventional process control systems tend to be expensive and usually perform on the functions initially identified by a user or a system designer that are only altered or reprogrammed to perform new functions by an expert who is familiar with the entire control system configuration and programming.

- What is needed is a uniform or universal design environment that can easily be used, not only by a designer or manufacturer but also a user, to customize an existing solution to meet his specific needs for developing process control functions.

- What is further needed is a personal computer-based process control system that is easily implemented within substantially any size process and which is updated by users, without the aid of the control system designer, to perform new and different control functions.

- Many process control systems include local field devices such as valves, motors, regulators and the like which are responsive to specific control protocols, such as Profibus, Fieldbus, CAN and the like, to implement various control function routines. Accordingly, these controllers are responsive to certain standard control protocols to implement control functionality in the field. The use of such standard control signal protocols can reduce the time and effort of developing a control system because a designer can use the same types of control signals from all devices responsive to the control protocol.

- control devices are not responsive to standard control protocols. These devices are often responsive to other types of control signals such as digital ON/OFF signals, analog current signals or analog voltage signals.

- a system designer either has to avoid using field devices that are nonresponsive to an installed protocol, or develop systems that operate under one or more protocols.

- present day processing systems disadvantageously lack a capability to utilize both standard protocol control devices and devices that do not respond to control signals defined under the standard protocols.

- a process control program might be written in Fortran and require two inputs, calculate the average of the inputs and produce an output value equal to the average of the two inputs.

- This program could be termed the AVERAGE function and may be invoked and referenced through a graphical display for the control engineers.

- a typical graphical display may consist of a rectangular block having two inputs, one output, and a label designating the block as AVERAGE.

- a different program may be used to create a graphical representation of this same function for an operator to view the average value.

- these software programs are placed into a library of predefined user selectable features. The programs are identified by function blocks.

- a user may then invoke a function and select the predefined graphical representations to create different views for the operator, engineer, etc. by selecting one of a plurality of function blocks from the library for use in defining a process control solution rather than having to develop a completely new program in Fortran, for example.

- a group of standardized functions, each designated by an associated function block, may be stored in a control library.

- a designer equipped with such a library can design process control solutions by interconnecting, on a computer display screen, various functions or elements selected with the function blocks to perform particular tasks.

- the microprocessor or computer associates each of the functions or elements defined by the function blocks with predefined templates stored in the library and relates each of the program functions or elements to each other according to the interconnections desired by the designer.

- a designer could design an entire process control program using graphical views of predefined functions without ever writing one line of code in Fortran or other high-level programming language.

- New process control functions are designed primarily by companies who sell design systems and not by the end users who may have a particular need for a function that is not a part of the standard set of functions supplied by the company.

- the standardized functions are contained within a control library furnished with the system to the end user.

- the end user must either utilize existing functions supplied with the design environment or rely on the company supplying the design environment to develop any desired particular customized function for them. If the designer is asked to modify the parameters of the engineer's view, then all other views using those parameters have to be rewritten and modified accordingly because the function program and view programs are often developed independently and are not part of an integrated development environment. Clearly, such procedure is very cumbersome, expensive, and time-consuming.

- process control systems are typically constrained to a particular size and difficult to adapt over time to arising needs.

- process control systems are inflexible in configuration, often requiring a complete software revision for the entire system when new devices are incorporated.

- the conventional process control systems tend to be expensive and usually perform on the functions initially identified by a user or a system designer that are only altered or reprogrammed to perform new functions by an expert who is familiar with the entire control system configuration and programming.

- a further problem with existing process control systems is that the physical implementation of different systems is highly variable, including control devices and field devices that have a wide range of "intelligence". For example, some field devices, such as valves, motors and regulators, may have no computational or control capability. Other field devices may have a high level of control autonomy. Still other devices may have some computational strength, but not a sufficient amount to accomplish a desired control task.

- What is needed is a uniform or universal design environment that can easily be used, not only by a designer or manufacturer but also a user, to customize a control process to the physical constraints of the process, utilizing control capabilities various controllers and devices, supplementing these control capabilities when desired and distributing control functionality flexibly throughout the process control system to meet specific needs for developing process control functions.

- What is further needed is a personal computer-based process control system that is easily implemented within substantially any size process and which is updated by users, without the aid of the control system designer, to perform new and different control functions by distributing these control functions throughout the control system including all central, intermediate and peripheral levels.

- Diagnostic information is one type of information that is useful to monitor and display in a process control system.

- diagnostic information is not generally monitored in a consistent manner from one device to the next.

- important diagnostic information typically relates to the interaction of multiple portions of the control system, for example, the combined operations of a controller and device or multiple devices and controllers.

- Diagnostic information relating to multiple circuits in a system is typically not handled by existing process control systems. Diagnostic information is most useful when related to the various control operations that are occurring when the diagnostic information is monitored.

- Conventional process control systems typically access and display diagnostic information with no relation to the control operations or control schemes that are functioning during diagnostic testing.

- One problem associated with the use of graphical views for diagnostic displays is that existing systems allow only the equipment manufacturer, not a user of this equipment, to define the diagnostic information to be monitored, along with associated graphical views, or modify the predefined diagnostic functions within the provided library.

- What is needed is a uniform or universal design environment that can easily be used, not only by a designer or manufacturer but also a user, to customize monitoring and display of diagnostic operations for a variable number and type of devices and components of a process control system.

- What is further needed is a personal computer-based process control system that includes a flexible diagnostic monitoring and display functionality that is easily implemented within substantially any size process and which is updated by users, without the aid of the control system designer, to monitor and display diagnostic information for various combinations of process field devices.

- the local field devices are typically configured in the field, often by individually programming the local field devices using a hand-held field programmer.

- Individual programming of the field devices is time consuming and inefficient and often leads to incompatibilities between the device configuration and the configuration of other devices and controllers in the process conttol system since a global view of the system is more difficult to sustain when individual devices are programmed independently. Usage of individual programming devices is inconvenient since multiple different programming devices typically must be used to program respective different field devices.

- What is needed is a process conttol system that allows individual field devices to be configured without local, independent programming. What is further needed is a process control system which allows configuration of the global system from a location remote from the local field devices so that a compatible global configuration is achieved while allowing peripheral elements which are configured in a suitable global manner, to operate independently to achieve control functionality.

- Configuration of the global system is based on parameters that describe the particular field devices that make up the system.

- the conttol protocols for communicating with the field devices may be insufficient to convey parameters that are sufficient to configure the system.

- the system management specification of the Fieldbus protocol defines three states for a device including an INITIALIZED state, an UNINITIALIZED state, and a system management operational (SM OPERATIONAL) state.

- the three defined states are sufficient to describe the behavior of a device from the perspective of the system management, but are not adequate for describing a device from the perspective of either the fieldbus interface or software engineering tools for analyzing, controlling, or displaying the status of a device.

- This insufficiency is highly notable when configuration involves the operation of commissioning a device that is attached to the Fieldbus link in an UNTNITIALIZED state.

- conttol languages have been developed under an IEC-1131 standard which assist a user in implementing a conttol sttategy.

- These control languages include function blocks, sequential function charts, ladder logic and structured text.

- Each of these languages is directed to a particular type of user, including conttol engineers, conttol system designers, technicians, operators and maintenance workers.

- conttol engineers include conttol engineers, conttol system designers, technicians, operators and maintenance workers.

- These users have widely different levels and areas of experience, training and expertise.

- Different users typically view control systems from greatly different perspectives and seek a solution to very different problems, expressed in different manners. For example, a conttol configuration view of a conttol system designer may be nonsense to a maintenance worker and vice-versa.

- What is needed is a user interface which flexibly presents a configuration in a manner that is most understandable and useful to a particular type of user.

- Alarm and event information is one type of information that is highly critical to monitor and display in a process conttol system.

- alarm information is not generally monitored in a useful manner. For example, very different urgencies may exist with respect to a particular alarm. Some alarm conditions may be indicative merely that some routine servicing should take place without urgency. Other alarm conditions require immediate attention. Certain devices in the process control system may measure highly critical conditions while other devices monitor much less urgent information.

- important some alarm conditions may relate to information the interaction of multiple portions of the conttol system, for example, the combined operations of a controller and device or multiple devices and controllers. Alarm conditions relating to multiple circuits and devices in a system are typically not handled by existing process conttol systems.

- Alarm and event information is most useful when related to the various conttol operations that are occurring when the conditions are monitored.

- Conventional process conttol systems typically access and display alarm information with no relation to the conttol operations or conttol schemes that are functioning during diagnostic testing.

- Conventional process conttol systems generally do not have a consistent system for setting priority of different alarm conditions and events.

- One problem associated with the use of graphical views for alarm and event displays is that existing systems allow only the equipment manufacturer, not a user of this equipment, to define the alarms and events to be monitored, along with associated graphical views, or modify predefined event priorities.

- Different types of users may need to visualize different aspects of the process conttol system. For example, some users have a capability to change only some operating aspects of the conttol system. These users should have access to condition information which they can control while for other events that may be controlled by another user, alarm information is not urgently needed.

- What is needed is a uriiform or universal design environment that can easily be used, not only by a designer or manufacturer but also a user, to prioritize display of alarm and event information.

- a process controller implements smart field device standards and other bus-based architecture standards so that communications and control among devices are performed so that the standard conttol operations are transparent to a user.

- the process controller allows attachment to a theoretically and substantially unlimited number and type of field devices including smart devices and conventional non-smart devices. Control and communication operations of the various numbers and types of devices are performed simultaneously and in parallel.

- the described design environment enables a process conttol designer or user to modify a standard process conttol function or create a unique customized process conttol function and create the graphical views to be associated with the modified or newly created process control function, all within a common environment.

- the design environment includes a common interface for both the creation of the function and for its associated engineers, operators, lab and maintenance personnel or other desired users such that when the engineer's function is modified or created, the modification or creation manifests itself in all other graphical views of the function.

- the design environment has a common database structure of attributes and methods and the graphics associated with the process conttol function to allow modified or created process conttol functions to be represented in whatever graphical methodology that is desired or required by the designer, whether by ladder logic, continuous function block or other design languages required by the various engineer, operator, lab, and maintenance personnel as other desired graphical views.

- conttol operations are dispersed throughout the conttol system, avoiding the inflexibility that arises from centralized conttol.

- the conttol system is personal-computer (PC) based and, therefore, inexpensive in comparison to mainframe based systems, easily upgraded as additional processes are added to the system, and conveniently operated by multiple users.

- the PC-based conttol is further advantageous in allowing user-friendly programming and display platforms such as Windows 95TM and Windows NTTM.

- a process controller implements and executes a standard set of function blocks or conttol functions defined by a standard protocol so that standard-type conttol is achieved with respect to non-standard-type devices.

- the process controller enables standard devices to implement the standard set of function blocks and conttol functions.

- the process controller implements an overall sttategy as if all connected devices are standard devices by usage of a function block as a fundamental building block for conttol structures. These function blocks are defined to create conttol structures for all types of devices.

- One advantage is that the system is highly uniform, whether attached devices are standard protocol devices or nonstandard devices, thereby improving system reliability.

- a further advantage is that system development costs are greatly reduced by handling various devices in a uniform manner.

- Another advantage is that a wide range of different field devices are supported so that intelligent devices utilize the intelligent capabilities and "dumb" devices are controlled by other controllers.

- An additional advantage is that a software routine performing a particular routine is highly re-usable, improving software reliability.

- a process controller implements an overall, user-developed conttol strategy in a process conttol network that includes distributed controller and field devices, such as Fieldbus and non-Fieldbus devices.

- a user defines the conttol sttategy by building a plurality of function blocks and control modules and downloading or installing user-specified portions of the conttol strategy into the Fieldbus devices and the non-Fieldbus devices. Thereafter, the Fieldbus devices automatically perform the downloaded portions of the overall strategy independently of other portions of the conttol sttategy.

- portions of the conttol sttategy downloaded or installed into the field devices operate independently of and in parallel with the control operations of the controllers and the workstations, while other conttol operations manage the Fieldbus devices and implement other portions of the control sttategy.

- the described process conttol system and operating method has many advantages.

- One advantage is that the system supplies a uniform, universal design environment for users of many various expertise, experience and training levels to customize a conttol process to the physical constraints of the process.

- a further advantage is that the described system uses conttol capabilities of various controllers and devices, supplementing these control capabilities when desired and distributing conttol functionality flexibly throughout the process conttol system as needed.

- Another advantage is that the process conttol system is easily based on a personal computer-based design which is easily implemented within substantially any size process and which is updated by users, without the aid of the conttol system designer, to perform new and different control functions. This flexibility is achieved by distributing conttol functions throughout the conttol system including all central, intermediate and peripheral levels.

- a process conttol system includes a diagnostic monitoring and display functionality for viewing, in a coherent manner, diagnostic information relating to a process that operates over multiple devices and system components.

- the process conttol system incorporates diagnostic information relating to all devices and presents this information to a system user in a uniform manner so that an operating conttol strategy and the diagnostic information are presented as though all conttol actions and diagnostic information were performed or generated at a single location.

- a user-defined diagnostic program is assembled as a set of function blocks and conttol modules and represented as a set of layers of interconnected conttol objects identified as modules which include informational structures accessed as attributes. Information is accessed using device hierarchy attribute addressing, supporting direct addressing of I/O signals from modules, bypassing the use of I/O function blocks and avoiding I/O function block behavior.

- One advantage is that the conttol scheme and the diagnostic monitoring are configured in the system in the same manner, saving system resources and improving system reliability. Another advantage is that configuration of the diagnostics is highly versatile, achieving a wide range of diagnostic behaviors. A further advantage is that the same display objects and procedures are used to display all types of information including configuration information, status information, diagnostics and virtually any other information generated or stored in the system.

- a digital conttol system automatically senses when a new controller is attached to a network and determines the number and types of I/O Ports that are attached to the new controller.

- the digital conttol system formats and displays the I/O Port information upon request by a user.

- the digital conttol system program also includes an automatic configuration program that responds to sensing of a new controller by automatically configuring the input/output (I/O) subsystem.

- the user adds a new controller without setting any physical switches or nodes.

- a user optionally supplies configuration information for a device into a database, prior to connection of a device. Upon connection of the device, the device is automatically sensed and configured using the database configuration information, without setting of physical switches on the devices.

- a method of automatically sensing a connection of a controller to a network and incorporating the controller into a network operating system includes the steps of connecting a controller to the network, sending a request from the controller to confirm a network address assignment, the request being accompanied by the controller media access conttol (MAC) address, a network configuration service receiving the request to confirm and responding.

- the network configuration service responds by performing the steps of searching a table of configured devices for a matching MAC address and, when the MAC address matches, generating device and network information.

- the device and network information includes a network address from a device table.

- network configuration service When the MAC address does not match, network configuration service generates device and network information including a network address from MAC address-based default information and adds the default information to the device table. When the MAC address does not match, the network configuration service further performs the step of assigning the connected controller under user conttol either as a new device added to the device table or as a device configuration previously existing in the device table.

- One advantage is that field devices are programmed from a remote location so that individual field setting of the devices, using a local setting device, is not necessary. Central programmability is highly useful to reduce system management costs and for reducing downtime of a process conttol system. A further advantage is that configuration of the entire system, rather setting of individual devices, leads to a system in which individual system settings are highly compatible.

- a conttol system controls one or more interconnected devices according to a defined conttol configuration.

- the conttol system automatically senses a device that is connected to the conttol system but not included in the control configuration definition.

- the conttol system supplies initial interconnect information to the connected device sufficient to upload configuration parameters from the device to the conttol system.

- a digital conttol system with a predetermined configuration automatically senses the connection to a network of a digital device that is not included in the predetermined configuration.

- the digital device is assigned temporary address information and placed in a temporary state, called a standby state, in which the digital device supplies information to the digital conttol system allowing a user to access the digital device including access of device information and configuration parameters.

- a user selectively commissions the digital device by assigning a physical device tag, and a device address, and installing a conttol strategy to the digital device, thereby placing the digital device in an operational state in communication with the digital conttol system.

- a user In the standby state, a user interrogates to determine the type of device that is attached, determines the role of the device in the context of the digital conttol system, assigns a physical device tag that assigns the determined role to the device, and verifies connection of the device to the network. Also in the standby state, the user initiates other applications applied to the device, including calibration of the device and configuring the device within the overall conttol scheme of the digital conttol system.

- a control system differentiates between Fieldbus device states beyond the states defined according to the Fieldbus standard specification.

- the conttol system sets a physical device tag equal to the device identification (ID) for the devices that do not have tags, while the device is autosensed.

- a device attached to the Fieldbus link with the physical device tag set equal to the device LD is controlled in the manner of an UNINTTIALIZED device.

- a process control system includes a user interface which supports multiple IEC-1131 standard control languages and user-selection from among the conttol languages. From a single application routine, a user selects a conttol language from among a plurality of conttol languages including, for example, Function Blocks, Sequential Function Charts, Ladder Logic and Structured Text, to implement a conttol strategy.

- a method for configuring a process control environment controlled by a computer system having a processor connected to a display device includes the step of providing a plurality of instructional sections.

- An instructional section sets forth information relating to configuring the process conttol environment.

- the method also includes the steps of selecting a conttol language editor for defining a process control environment configuration, displaying on the display device a sequence of configuration screen presentations relating to the instruction sections as directed in terms of the selected conttol language editor; and guiding a user through the configuration of the process control environment via the sequence of configuration screen presentations.

- One advantage is that many different users are supported by the system so that users having a wide range of expertise and experience can easily use the system. Furthermore, the system is highly useful for a single user to tailor various aspects of the system using a most appropriate language for a particular system aspect.

- a process control system includes an alarm and event monitoring and display system for which various users of the system can easily prioritize the alarm and event information that is displayed.

- the alarm and event configuration is highly flexible and is configured by a user to display particular events in a hierarchical manner, as directed by the user. The user sets a desired alarm priority, selecting high importance alarms for more urgent display and annunciation and rendering a lower display status to less urgent events.

- a particular system user is associated with a display configuration for displaying alarm and event information that is pertinent to that user and the process conttol system is automatically "primed" with current alarms and initiate process information about new alarm and event occurrences.

- One advantage is that alarm information is presented to a user who can best use that information in a manner directed by the user. Another advantage is that a user attains access to the appropriate information automatically, at log-on. A further advantage is that the information stream is "primed" when a user logs on so that pertinent alarm events begin immediate accumulation for that user.

- FIGURES 1A, IB and IC illustrate a screen display, a first schematic block diagram and a second schematic block diagram, respectively, process control systems in accordance with a generalized embodiment of the present invention which furnishes a capability to create a new conttol template and a capability to modify an existing control template for only one view, such as an engineering view.

- FIGURE 2 is a schematic block diagram showing the process conttol environment in a configuration implementation and a run-time implementation.

- FIGURE 3 is a block diagram illustrating a user interface for usage with both configuration and run-time models of the process control environment.

- FIGURE 4 is a schematic block diagram which depicts a hierarchical relationship among system objects of a configuration model in accordance with an embodiment of the present invention.

- FIGURE 5 is a schematic block diagram which depicts a configuration architecture that operates within the hierarchical relationship illustrated in FIGURE 4.

- FIGURE 6 is a block diagram illustrating an example of an elemental function block, which is one type of system object within the configuration model definition.

- FIGURE 7 is a block diagram depicting an example of a composite function block, which is another type of system object within the configuration model definition.

- FIGURE 8 is a block diagram illustrating an example of a conttol module, which is another type of system object within the configuration model definition.

- FIGURE 9 is a block diagram showing a module instance, specifically a control module instance, which is created in accordance with the control module definition depicted in FIGURE 8.

- FIGURE 10 is a flow chart which shows an example of execution of a conttol module at run-time.

- FIGURE 11 is a flow chart which shows an example of a module at a highest layer of a conttol structure.

- FIGURE 12 is a block diagram which illusttates an object-oriented method for installing a process I/O attribute block into a PIO device.

- FIGURE 13 is a block diagram depicting an object-oriented method for linking a conttol module input attribute to a PIO attribute.

- FIGURE 14 is a block diagram showing an object-oriented method for linking a conttol module output attribute to a PIO attribute.

- FIGURE 15 is a block diagram showing an object-oriented method for reading values of contained PIO attributes.

- FIGURE 16 is a block diagram which illusttates an organization of information for an instrument signal tag.

- FIGURE 17 is a flow chart illustrating a method for bootsttap loading a conttol system throughout a network in the process conttol environment.

- FIGURE 18 is an object communication diagram illustrating a method for creating a device connection for an active, originating side of the connection.

- FIGURE 19 is an object communication diagram illustrating a method for creating a device connection for a passive, listening side of the connection.

- FIGURE 20 is an object communication diagram illustrating a method for sending request response messages between devices.

- FIGURE 21 is an object communication diagram illustrating a method of downloading a network configuration.

- FIGURE 22 is a pictorial view of a front-of-screen display which illusttates a flowchart of the operations of a diagnostic display routine.

- FIGURE 23 is an object communication diagram illustrating a method for one device to check whether another device exists on a network.

- FIGURE 24 is an object communication diagram illustrating a method for requesting device communications diagnostics.

- FIGURE 25 is an object communication diagram illustrating a method for requesting device connection communications diagnostics.

- FIGURE 26 illustrates a method for automatically sensing and incorporating a controller/ multiplexer into a run-time system.

- FIGURE 27 is a flow chart illusttates steps of an automatic configuration routine for configuring a physical I/O device.

- FIGURE 28 is a pictorial view of a front-of-screen display for a graphical user interface (GUI) displaying a system configuration.

- GUI graphical user interface

- FIGURE 29 is a state transition diagram illustrating various states of a field device.

- FIGURE 30 is a flow chart illustrating a first operation of commissioning a new device.

- FIGURE 31 is a flow chart illustrating a second operation of commissioning an unbound.

- FIGURE 32 is a flow chart illustrating a third operation of decommissioning a device.

- FIGURE 33 is a flow chart illustrating a fourth operation of attaching a commissioned device without enablement of operational powerap.

- FIGURE 34 is a flow chart illustrating a fifth operation of replacing a device.

- FIGURE 35 is a flow chart illustrating a sixth operation of attaching an UNRECOGNIZED device.

- FIGURE 36 is a flow chart illustrating a seventh operation of decommissioning an unrecognized device.

- FIGURE 37 is a flow chart illustrating an eighth operation of placing a decommissioned device in a standby condition.

- FIGURE 38 is a schematic block diagram which illusttates a program structure of a process conttol configuration program for defining a process configuration using a plurality of conttol languages.

- FIGURES 39A through 39E are multiple screen presentations showing configuration, selection and choice screens that are invoked by a configuration program during operation of a configuration operation using a functional block conttol language and a sequential function chart control language.

- FIGURE 40 is an object model showing object relationships of various objects for handling alarm and event functions.

- FIGURE 41 is a state transition diagram which depicts alarm attribute states.

- FIGURE 42 is a context diagram showing a context for defining an alarm event with respect to a control module.

- FIGURE 43 is an object communication diagram illustrating a method for performing an attribute write operation that evokes an "in alarm” status.

- the system 1 includes a main processing device, such as personal computer 2, that is connected to a local area network (“LAN") 3 via a local area network card.

- LAN local area network

- a non-proprietary ethernet protocol is beneficial in many applications because it allows for communications with the local area network 3.

- the local area network 3 is dedicated to carrying control parameters, conttol data and other relevant information concerned in the process control system.

- the LAN 3 may be referred to as an area controlled network or ACN 3.

- the ACN 3 may be connected to other LANs for sharing information and data via a hub or gateway without affecting the dedicated nature of ACN 3.

- a plurality of physical devices may be connected to the ACN 3 at various "nodes.” Each physical device connected to the ACN 3 is connected at a node and each node is separately addressable according the LAN protocol used to implement ACN 3.

- ACN 3 may be desirable to construct ACN 3 from two or more ethernet systems such that the failure of a single ethernet or LAN system will not result in the failure of the entire system.

- redundant ethernets the failure of one ethernet LAN can be detected and an alternate ethernet LAN can be mapped in to provide for the desired functionality of ACN 3.

- the main personal computer (“PC") A forms a node on the ACN 3.

- the PC 2 may, for example, be a standard personal computer running a standard operating system such as Microsoft's Window NT system.

- Main PC 2 is configured to generate, in response to user input commands, various conttol routines that are provided via the ACN 3 to one or more local controllers identified as element 4 and 5 which implement the conttol strategy defined by the conttol routines selected and established in main PC 2.

- Main PC 2 may also be configured to implement direct conttol routines on field devices such as pumps, valves, motors and the like via transmission across the ACN 3, rather than through a local controller 4 or 5.

- Local conttollers 4 and 5 receive control routines and other configuration data through the ACN 3 from PC 2.

- the local conttollers then generate signals of various types to various field devices (such as pumps, motors, regulator valves, etc.) 6 through 15 which actually implement and perform physical steps in the field to implement the conttol system established by the routines provided by PC 2.

- field devices such as pumps, motors, regulator valves, etc.

- Two types of field devices may be connected to local conttoller 4 and 5 including field devices 6 through 10 which are responsive to specific conttol protocol such as FieldBus, Profibus and the like.

- conttol protocols e.g. FieldBus

- a protocol-friendly field devices e.g., a Fieldbus field devices

- field devices 6 through 11 receive protocol specific (e.g., FieldBus) conttol commands from either the local controllers 4 and 5 or the personal computer 2 to implement a field device- specific function.

- non-protocol field devices 12 through 15 are Also connected to local conttollers 4 and 5 are non-protocol field devices 12 through 15, which are referred to as non-protocol because they do not include any local processing power and can respond to direct conttol signals. Accordingly, field devices 12 through 15 are not capable of implementing functions that would be defined by specific conttol protocol such as the FieldBus conttol protocol.

- Protocol-friendly e.g., FieldBus specific

- this same functionality allows for the implementation of the protocol-specific conttol routines to be distributed between the local field devices 6 through 11, the local conttollers 4 and 5 and the personal computer 2.

- FIGURE IB refers to one portion of the system shown in FIGURE 1A, specifically the personal computer 2, the ethernet 3, local conttoller 4, a smart field device 6 and a dumb device 12, in greater detail.

- Personal computer 2 includes program software routines for implementing standard functional routines of a standard conttol protocol such as the FieldBus protocol. Accordingly, personal computer 2 is programmed to receive FieldBus commands and to implement all of the functional routines for which a local field device having Fieldbus capabilities could implement. The ability and steps required to program personal computer 2 to implement FieldBus block functionality will be clearly apparent to one of ordinary skill in the art.

- Local conttoller 4 includes a centtal processing unit connected to a random access memory which provides conttol signals to configure the central processing unit to implement appropriate operational functions.

- a read only memory is connected to the random access memory.

- the read only memory is programmed to include conttol routines which can configure the centtal processing unit to implement all of the functional routines of a standard conttol protocol such as FieldBus.

- Personal computer 2 sends signals through ethernet 3 to the local conttoller 4 which causes one, more or all of the programmer routines in the read only memory to be transferred to the random access memory to configure the CPU to implement one, more or all of the standard control protocol routines such as the FieldBus routines.

- the smart field device 6 includes a centtal processing unit which implements certain conttol functions. If the devices is, for example, a FieldBus device then the centtal processing unit associated with the field device 6 is capable of implementing all of the FieldBus functionality requirements.

- conttoller 4 operates so that non-protocol device 12 acts and is operated as a FieldBus device. For example, if a conttol routine is running either in personal computer 2 or on the CPU of local conttoller 4, that conttol routine can implement and provide FieldBus commands to FieldBus device 6 and non-protocol device 12, operating as a Fieldbus device. Since field device 6 is a FieldBus device, device 6 receives these commands and thereby implements the control functionality dictated by those commands. Non-protocol device 12, however, works in conjunction with the centtal processing unit of local conttoller 4 to implement the FieldBus requirements such that the local conttoller in combination with the field device implements and operates FieldBus commands.

- non-FieldBus device 12 In addition to allowing non-FieldBus device 12 to act and operate as a FieldBus device, the described aspect allows for distribution of FieldBus conttol routines throughout the system 1 shown in FIGURE 1A.

- the system 1 allows for conttol to be divided between the local controller 4 and the local conttoller 5 such that a portion of the FieldBus conttol routines are being implemented by local controller 5 and other FieldBus routines are implemented by the use of the FieldBus routines stored on local conttoller 4.

- the division of FieldBus routine implementation may allow for more sophisticated and faster control and more efficient utilization of the overall processing power of the system.

- the FieldBus routines are further distributed between the local conttoller 4 and the personal computer 2. In this manner, the system allows personal computer 2 to implement one or all of the FieldBus routines for a particular control algorithm.

- system allows for the implementation of FieldBus controls to a non-FieldBus device connected directly to the ethernet 3 through use of the FieldBus conttol routines stored on personal computer 2 in the same manner that FieldBus routines are implemented on non-FieldBus device 12 through use on the FieldBus routines stored on local conttoller 4.

- a process conttol environment 100 is shown in FIGURE IC and illustrates a conttol environment for implementing a digital conttol system, process conttoller or the like.

- the process conttol environment 100 includes an operator workstation 102, a laboratory workstation 104, and an engineering workstation 106 electrically interconnected by a local area network (“LAN") 108 for transferring and receiving data and conttol signals among the various workstations and a plurality of controller/multiplexers 110.

- the workstations 102, 104, 106 are shown connected by the LAN 108 to a plurality of the controller/multiplexers 110 that electrically interface between the workstations and a plurality of processes 112.

- the LAN 108 includes a single workstation connected directly to a controller/multiplexer 110 or alternatively includes a plurality of workstations, for example three workstations 102, 104, 106, and many controller/multiplexers 110 depending upon the purposes and requirements of the process control environment 100.

- a single process controller/multiplexer 110 controls several different processes 112 or alternatively controls a portion of a single process.

- a process conttol sttategy is developed by creating a software conttol solution on the engineering workstation 106, for example, and transferring the solution via the LAN 108 to the operator workstation 102, lab workstation 104, and to controller/multiplexer 110 for execution.

- the operator workstation 102 and lab workstation 104 supply interface displays to the control/monitor sttategy implemented in the controller/multiplexer 110 and communicates to one or more of the controller/multiplexers 110 to view the processes 112 and change conttol attribute values according to the requirements of the designed solution.

- the processes 112 are formed from one or more field devices, which may be smart field devices or conventional (non-smart) field devices.

- the process 112 is illustratively depicted as two Fieldbus devices 132, a HART (highway addressable remote transducer) device 134 and a conventional field device 136.

- the operator workstation 102 and lab workstation 104 communicate visual and audio feedback to the operator regarding the status and conditions of the controlled processes 112.

- the engineering workstation 106 includes a centtal processing unit (CPU) 116 and a display and input output or user-interface device 118 such as a keyboard, light pen and the like.

- the CPU 116 typically includes a dedicated memory 117.

- the dedicated memory 117 includes a digital conttol system program (not shown) that executes on the CPU 116 to implement conttol operations and functions of the process control environment 100 shown in FIGURE IC.

- the operator workstation 102, the lab workstation 104 and other workstations (not shown) within the process control environment 100 include at least one central processing unit (not shown) which is electrically connected to a display (not shown) and a user-interface device (not shown) to allow interaction between a user and the CPU.

- the process conttol environment 100 includes workstations implemented using a Motorola 68040 processor and a Motorola 68360 communications processor running in companion mode with the 68040 with primary and secondary ethernet ports driven by the 68360 processor (SCC1 and SCC3 respectively).

- the process conttol environment 100 also includes a template generator 124 and a conttol template library 123 which, in combination, form a control template system 120.

- a conttol template is defined as the grouping of attribute functions that are used to conttol a process and the methodology used for a particular process conttol function, the conttol attributes, variables, inputs, and outputs for the particular function and the graphical views of the function as needed such as an engineer view and an operator view.

- the control template system 120 includes the control template library 123 that communicates with the template generator 124.

- the conttol template library 123 contains data representing sets of predefined or existing conttol template functions for use in process conttol programs.

- the control template functions are the templates that generally come with the system from the system designer to the user.

- the template generator 124 is an interface that advantageously allows a user to create new conttol template functions or modify existing conttol template functions. The created and modified template functions are selectively stored in the conttol template library 123.

- the template generator 124 includes an attributes and methods language generator 126 and a graphics generator 128.

- the attributes and methods language generator 126 supplies display screens that allow the user to define a plurality of attribute functions associated with the creation of a new conttol template function or modification of a particular existing conttol template function, such as inputs, outputs, and other attributes, as well as providing display screens for enabling the user to select methods or programs that perform the new or modified function for the particular conttol template.

- the graphics generator 128 furnishes a user capability to design graphical views to be associated with particular conttol templates. A user utilizes the data stored by the attributes and methods language generator 126 and the graphics generator 128 to completely define the attributes, methods, and graphical views for a control template.

- the data representing the created conttol template function is generally stored in the conttol template library 123 and is subsequently available for selection and usage by an engineer for the design of process conttol solutions.

- the process conttol environment 100 is implemented using an object-oriented framework.

- An object-oriented framework uses object-oriented concepts such as class hierarchies, object states and object behavior. These concepts, which are briefly discussed below, are well known in the art. Additionally, an object-oriented framework may be written using object-oriented programming languages, such as the C++ programming language, which are well-known in the art, or may be written, as is the case with the preferred embodiment, using a non-object programming language such as C and implementing an object-oriented framework in that language.

- the building block of an object-oriented framework is an object.

- An object is defined by a state and a behavior.

- the state of an object is set forth by fields of the object.

- the behavior of an object is set forth by methods of the object.

- Each object is an instance of a class, which provides a template for the object.

- a class defines zero or more fields and zero or more methods.

- Fields are data structures which contain information defining a portion of the state of an object. Objects which are instances of the same class have the same fields. However, the particular information contained within the fields of the objects can vary from object to object. Each field can contain information that is direct, such as an integer value, or indirect, such as a reference to another object.

- a method is a collection of computer instructions which can be executed in CPU 116 by computer system software.

- the instructions of a method are executed, i.e., the method is performed, when software requests that the object for which the method is defined perform the method.

- a method can be performed by any object that is a member of the class that includes the method.

- the particular object performing the method is the responder or the responding object.

- the responder consumes one or more arguments, i.e., input data, and produces zero or one result, i.e., an object returned as output data.

- the methods for a particular object define the behavior of that object.

- Classes of an object-oriented framework are organized in a class hierarchy.

- a class inherits the fields and methods which are defined by the superclasses of that class.

- the fields and methods defined by a class are inherited by any subclasses of the class. I.e., an instance of a subclass includes the fields defined by the superclass and can perform the methods defined by the superclass. Accordingly, when a method of an object is called, the method that is accessed may be defined in the class of which the object is a member or in any one of the superclasses of the class of which the object is a member.

- process control environment 100 selects the method to run by examining the class of the object and, if necessary, any superclasses of the object.

- a subclass may override or supersede a method definition which is inherited from a superclass to enhance or change the behavior of the subclass.

- a subclass may not supersede the signature of the method.

- the signature of a method includes the method's identifier, the number and type of arguments, whether a result is returned, and, if so, the type of the result.

- the subclass supersedes an inherited method definition by redefining the computer instructions which are carried out in performance of the method.

- Classes which are capable of having instances are concrete classes. Classes which cannot have instances are abstract classes. Abstract classes may define fields and methods which are inherited by subclasses of the abstract classes. The subclasses of an abstract class may be other abstract classes; however, ultimately, within the class hierarchy, the subclasses are concrete classes.

- the process control environment 100 exists in a configuration model or configuration implementation 210 and a run-time model or run-time implementation 220 shown in FIGURE 2.

- the configuration implementation 210 the component devices, objects, interconnections and interrelationships within the process conttol environment 100 are defined.

- the run-time implementation 220 operations of the various component devices, objects, interconnections and interrelationships are performed.

- the configuration implementation 210 and the run-time implementation 220 are interconnected by downloading.

- the download language creates system objects according to definitions supplied by a user and creates instances from the supplied definitions. Specifically, a completely configured Device Table relating to each device is downloaded to all Workstations on startup and when the Device Table is changed.

- a downloaded Device Table only includes data for devices for which the controller/ multiplexer 110 is to initiate communications based on remote module data configured and used in the specific controller/ multiplexer 110.

- the Device Table is downloaded to the controller/ multiplexer 110 when other configuration data is downloaded.

- the download language also uploads instances and instance values.

- the configuration implementation 210 is activated to execute in the run-time implementation 220 using an installation procedure. Also, network communications parameters are downloaded to each device when configuration data are downloaded and when a value is changed.

- the process conttol environment 100 includes multiple subsystems with several of the subsystems having both a configuration and a run-time implementation.

- a process graphic subsystem 230 supplies user-defined views and operator interfacing to the architecture of the process control environment 100.

- the process graphic subsystem 230 has a process graphic editor 232, a part of the configuration implementation 210, and a process graphic viewer 234, a portion of the run-time implementation 220.

- the process graphic editor 232 is connected to the process graphic viewer 234 by an intersubsystem interface 236 in the download language.

- the process conttol environment 100 also includes a control subsystem 240 which configures and installs conttol modules and equipment modules in a definition and module editor 242 and which executes the conttol modules and the equipment modules in a run-time controller 244.

- the definition and module editor 242 operates within the configuration implementation 210 and the run-time conttoller 244 operates within the run-time implementation 220 to supply continuous and sequencing conttol functions.

- the definition and module editor 242 is connected to the run-time controller 244 by an intersubsystem interface 246 in the download language.

- the multiple subsystems are interconnected by a subsystem interface 250.

- the configuration implementation 210 and the run-time implementation 220 interface to a master database 260 to support access to common data structures.

- Various local (non-master) databases 262 interface to the master database 260, for example, to ttansfer configuration data from the master database 260 to the local databases 262 as directed by a user.

- Part of the master database 260 is a persistent database 270.

- the persistent database 270 is an object which transcends time so that the database continues to exist after the creator of the database no longer exists and transcends space so that the database is removable to an address space that is different from the address space at which the database was created.

- the entire configuration implementation 210 is stored in the persistent database 270.

- the master database 260 and local databases 262 are accessible so that documentation of configurations, statistics and diagnostics are available for documentation purposes.

- the run-time implementation 220 interfaces to the persistent database 270 and to local databases 262 to access data structures formed by the configuration implementation 210.

- the run-time implementation 220 fetches selected equipment modules, displays and the like from the local databases 262 and the persistent database 270.

- the run-time implementation 220 interfaces to other subsystems to install definitions, thereby installing objects that are used to create instances, when the definitions do not yet exist, instantiating run-time instances, and transferring information from various source to destination objects.

- Device Tables are elements of the configuration database that are local to devices and, in combination, define part of the configuration implementation 210.

- a Device Table contains information regarding a device in the process control environment 100.

- Information items in a Device Table include a device ID, a device name, a device type, a PCN network number, an ACN segment number, a simplex/ redundant communication flag, a conttoller MAC address, a comment field, a primary internet protocol (IP) address, a primary subnet mask, a secondary IP address and a secondary subnet mask.

- IP internet protocol

- a block diagram illusttates a user interface 300 for usage with both the configuration and run-time models of the process conttol environment 100.

- Part of the user interface 300 is the ExplorerTM 310, an interfacing program defined under the Windows NTTM operating system which features a device-based configuration approach.

- Another part of the user interface 300 is a module definition editor 320 for interfacing using a control-based configuration approach.

- the ExplorerTM 310 is operated by a user to select, construct and operate a configuration. In addition, the ExplorerTM 310 supplies an initial state for navigating across various tools and processors in a network. A user controls the ExplorerTM 310 to access libraries, areas, process control equipment and security operations.

- FIGURE 3 illusttates the relationship between various tools that may be accessed by a task operating within the process conttol environment 100 and the relationship between components of the process conttol environment 100 such as libraries, areas, process conttol equipment and security. For example, when a user selects a "show tags" function from within an area, a "tag list builder" is displayed, showing a list of conttol and I/O flags. From the tag list builder, the user can use an "add tag” function to add a module to a list, thereby invoking a "module editor”.

- a schematic block diagram illustrates a hierarchical relationship among system objects of a configuration model 400.

- the configuration model 400 includes many configuration aspects including conttol, I/O, process graphics, process equipment, alarms, history and events.

- the configuration model 400 also includes a device description and network topology layout.

- the configuration model hierarchy 400 is defined for usage by a particular set of users for visualizing system object relationships and locations and for communicating or navigating maintenance information among various system objects.

- one configuration model hierarchy 400 specifically a physical plant hierarchy, is defined for usage by maintenance engineers and technicians for visualizing physical plant relationships and locations and for communicating or navigating maintenance information among various instruments and equipment in a physical plant.

- An embodiment of a configuration model hierarchy 400 that forms a physical plant hierarchy supports a subset of the SP88 physical equipment standard hierarchy and includes a configuration model site 410, one or more physical plant areas 420, equipment modules 430 and control modules 440.

- the configuration model hierarchy 400 is defined for a single process site 410 which is divided into one or more named physical plant areas 420 that are defined within the configuration model hierarchy 400.

- the physical plant areas 420 optionally contain tagged modules, each of which is uniquely instantiated within the configuration model hierarchy 400.

- a physical plant area 420 optionally contains one or more equipment modules 430.

- An equipment module 430 optionally contains other equipment modules 430, control modules 440 and function blocks.

- An equipment module 430 includes and is controlled by a control template that is created according to one of a number of different graphical process conttol programming languages including continuous function block, ladder logic, or sequential function charting ("SFC").

- the configuration model hierarchy 400 optionally contains one or more control modules 440.

- a conttol module 440 is contained in an object such as a physical plant area 420, an equipment module 430 or another conttol module 440.

- a conttol module 440 optionally contains objects such as other conttol modules 440 or function blocks.

- the conttol module 440 is thus a container class, having instances which are collections of other objects.

- the conttol module 444 is encapsulated so that all of the contents and the implementation of the methods of the conttol module are hidden.

- a schematic block diagram shows a configuration architecture 500 that operates within the configuration model hierarchy 400 illustrated in FIGURE 4.

- the configuration architecture 500 includes a several objects and classes at multiple levels of absttaction.

- the configuration architecture 500 includes a site class 512 which contains "named" objects and classes within the configuration architecture 500.

- Named objects and classes are definitions, display components such as screens and graphics and other items.

- the named objects and classes include function blocks, user accounts, modules, plant areas, events, libraries and other site-wide information. Examples of named items are block definitions, equipment module definitions, conttol module definitions, plant area names and the like.

- the configuration architecture 500 includes primitives that define the interfaces to functions within the configuration architecture 500, including hard-coded functions such as "+".

- the primitive level of abstraction 520 includes the classes of functions 522 and parameters 524.

- Functions 522 are operational functions at the lowest level of absttaction in the configuration architecture 500. Functions 522 are typically coded in the C or C++ languages.

- the full set of implemented function blocks 522 are primitives.

- Objects and classes at the primitive level of abstraction 520 are defined throughout the site class 512.

- Parameters 524 are classes and objects at the lowest level of absttaction in the configuration architecture. Parameters 524 include integer numbers, real numbers, vectors, arrays and the like. Attribute values are mapped into parameters 524 for usage within a function block 522.

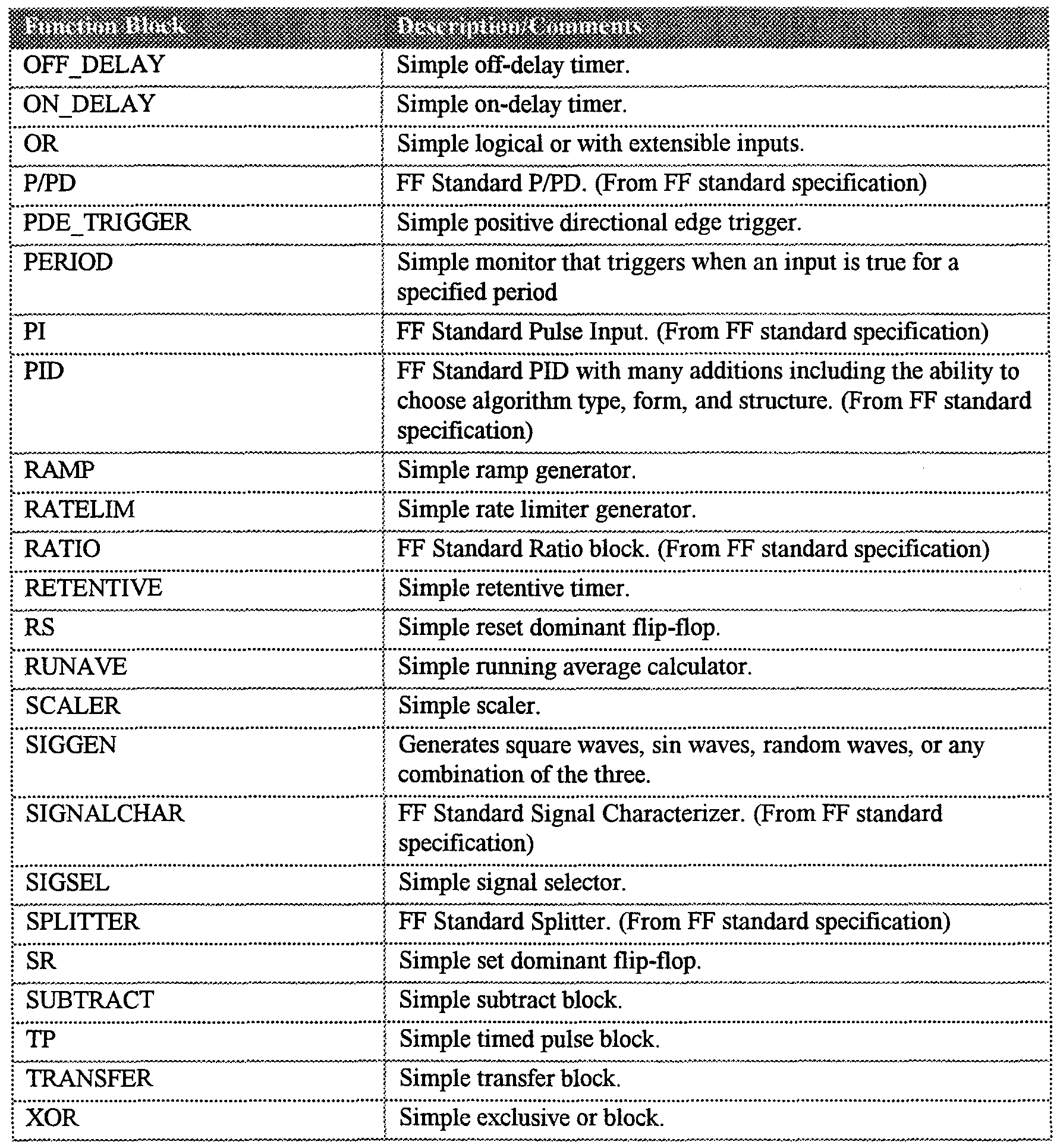

- function blocks 522 at the primitive level of absttaction 520 include the function block primitives listed in TABLE I, as follows:

- the configuration architecture 500 includes definitions 532 and usages.

- Definitions 532 and usages in combination, define the algorithm and the interface for objects including function blocks, control modules, equipment modules, links and attributes.

- the definitions 532 define algorithms and interfaces for function blocks, modules, links and attributes.

- Usages are objects and classes at the definition and usage level of absttaction 530 that represent the usage of one definition within another.

- the configuration architecture 500 includes instances, which are "tagged" items within the configuration.

- Plant areas 542, modules 544, attributes 546, and PIO blocks 548 are tagged instances. Instances are defined according to definitions 532.

- a plant area 542 represents a geographical or logical segmentation of a process site class 512. All objects and classes at the instance level of absttaction 540 are defined throughout the plant area level so that all module instances have a 0 or 1 association with a plant area 542. To be installed in a run-time system, the module instances must have a 1 association, meaning that the module is viewed as being "contained by" or “scoped” in this context of a plant area.

- a module instance 544 is an installable object that is associated to a specific object of plant equipment.

- An attribute instance 546 is a visible parameter in a module instance 544, a plant area instance 542 or other device.

- An attribute instance 546 may be used for an input signal, an output signal, data storage or the like.

- the configuration architecture 500 includes devices 552 such as controllers, smart devices and consoles, and input/output devices (10) 560 such as a PIO block, and the like, which represent physical process conttol equipment in the physical plant.

- a process input/output (PIO) block is an abstraction that represents various high density and low density conventional input/output devices including Hart, FieldBus and other input and output devices that are interfaced into the configuration architecture 500. High or low density relates to the number of channels on an I/O card. For example, 8 channels are typical on a low density card while a high density card may have 32 channels.

- Devices 552 are process conttol equipment in the configuration architecture 500 and include objects such as conttollers, input/output devices, consoles and the like.